Technologies and services for your products

With our high-tech machines and other processes, we can cut precise flame blanks to your specifications.

Burning

With the help of high-quality, modern machines, we produce the perfect part for every application. From single pieces to series and large batches with the shortest lead time according to your specifications. During production, we do not overlook any detail and can therefore guarantee precisely fitting solutions.

We are able to produce flame-cut parts in a variety of shapes and sizes according to the tolerance class DIN EN 9013 class 2 or according to individual agreement with you.

Shapes

Rectangles, drawing parts, moulded parts

with a length of up to 19,000 mm

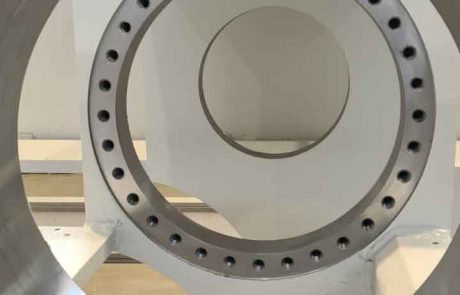

Circular blanks, rings

up to 5,200 mm diameter

Dimensions

Thicknesses: 2-20 mm

Working range: 4,500-38,000 mm (plasma)

Thicknesses: 20-300 mm

Working range 6,000-28,000 mm (oxyfuel)

Piece weights up to 40,000 kg

Additional processing

Application of welding bevels

Application of centre punch dots

Descaling

Priming

Heat treatment (stress relieving and normal annealing)

Restamping with TÜV approval

Restamping with Germanischer Lloyd approval

Straightening

Delivery

If required with works certificate 2.2 or acceptance test certificate 3.1

Acceptance by various classification societies with 3.2

Inspection for Z-properties

Autogenous firing system 1×12 burners and 1×6 burners

Our CNC-controlled autogenous firing plant produces dimensionally accurate firing blanks according to your drawings.

Burning thickness from 20 to 1,000 mm

Maximum burning width 6,000 mm

Burning length maximum 35,000 mm

Unit weight up to 40 t

Delivery programme flame-cut parts according to drawings (file format dxf or dgw), wide flats

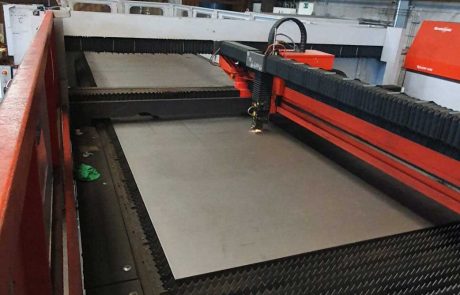

Lasering

With our system you can cut up to 12000 mm long flame-cut parts with the highest accuracy. We laser your XXL parts with a material thickness of up to 20 mm, main-taining high precision, also thanks to the use of highly specialized technology.

Cutting range

12,000 mm ✕ 2,500 mm

Material thickness

up to 20 mm

Laser system

Our system lasers your XXL flame-cut parts up to a material thickness of 20 mm and a total length of up to 12,000 mm. With a high-precision laser, we offer optimum fitting accuracy for your flame-cut parts. Strip and quarto plates can be processed.

Blasting

The shot blast machine allows further processing of sheet metal, plasma and au-togenous fired parts. The parts can be processed according to SA2 5 to ensure maximum protection against corrosion during the manufacturing process.

Throughput width

3,200 mm

Length

15,500 mm

Unit weights

up to 14 t

Blasting plant

We blast your sheet metal and flame-cut parts according to DIN EN ISO 12944|SA 2.5.

Throughput width 3200 mm

Passage length 15500 mm

Unit weights up to 14 t

Welding

We offer a comprehensive range of services for your welding needs. From system solutions for steel and mechanical engineering to contract manufacturing with other related areas such as materials handling or components – we are a reliable partner at your side.

In order to guarantee high quality, we are currently being certified in accordance with EN 1090-2 EXC3 and EN ISO 3834-3.

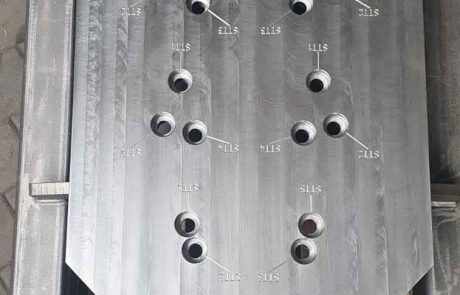

Restamping

We are proud to be certified by TÜV Nord and Germanischer Lloyd. Our company is certified to independently press low stress stamps onto our sheet metal and flame cut parts.

Furthermore, we can offer low stress stamps that meet the standards of TÜV Nord and DNV-GL.

Due to the approval of the TÜV Nord as well as the DNV-GL, we are able to independently stamp low-stress stamps on your sheets and flame-cut parts. The stamping can be applied to the upper side of the material and to the lateral edges (from 20 mm thickness).

Coating

We are experts in surface treatment, from priming to sandblasting. We know how important it is to care for and protect your delicate components. That’s why we do everything we can to make sure it’s delivered exactly the way you want it.

Seawater resistance similar to C5, duplex coating,

Hot-dip galvanised ISO 1461

Own specification up to DIN EN ISO 12944-C3,

Protection time k/m/l

Components

We supply all the components you need for your next project so it can be done quickly and efficiently. Whether you need a separation in one plane or in multiple planes, with or without chamfer, we will make your individual requirement to fit.

- Sheet metal, tube, bar steel construction

- Single pieces, small or medium series

(also Just-In-Sequence), special constructions - up to 25 to (up to 50 to special constructions)

- up to 15m length, 5m width and 6m height

Plasma

The dimensionally accurate flame cuts of our CNC-controlled plasma cutting sys-tem help you make the most of your ideas.

Firing thickness Thickness range from 2 to 25 mm

Firing width maximum 4,200 mm

Firing length maximum 39,000 mm

Delivery programme Burning parts according to drawings in the file formats dxf or dwg

Plasma system

Our CNC-controlled plasma cutting system produces dimensionally accurate flame-cut parts according to your drawings. Burning thickness: Thickness range from 2 to 25 mm Burning width: Maximum 4,200 mm Burning length: Maximum 39,000 mm Delivery programme: Burning parts according to drawings in the file formats dxf or dwg

Chamfering

We chamfer your flame-cut parts up to a depth of 200 mm with our high-precision robot. This ensures repeatable results, saving you time and money in the long run.

Plasma and autogenous chamfering

Chamfer width 5-50 mm

Chamfer depth up to 200 mm

Chamfer shape

V, V-with web, double V, double V with web HY X K flat chamfers (top up to 30° bottom up to 20°) 4-fold chamfers

FASRAPID

Max. stroke (mm): 3000

Max. chamfer width(mm): 60

Material thickness (mm): 4-40

Chamfer angle (degrees): -60-0

CHAMFERING ROBOT

Plasma and autogenous chamfering

5-50 mm-up to 200 mm

Chamfer shape:

- V, V-with land, Double-V, Double-V with land

- HY

- X

- K

- flat bevels (top up to 30° bottom up to 20°)

- 4-fold chamfers